Injection Moulding

At Axion, we take your plastic parts from concept to mass production. We bridge the gap between prototyping and manufacturing by offering comprehensive tooling and moulding solutions under one roof.

From Prototype to Mass Production

We tailor our tooling strategies to your project's lifecycle and budget:

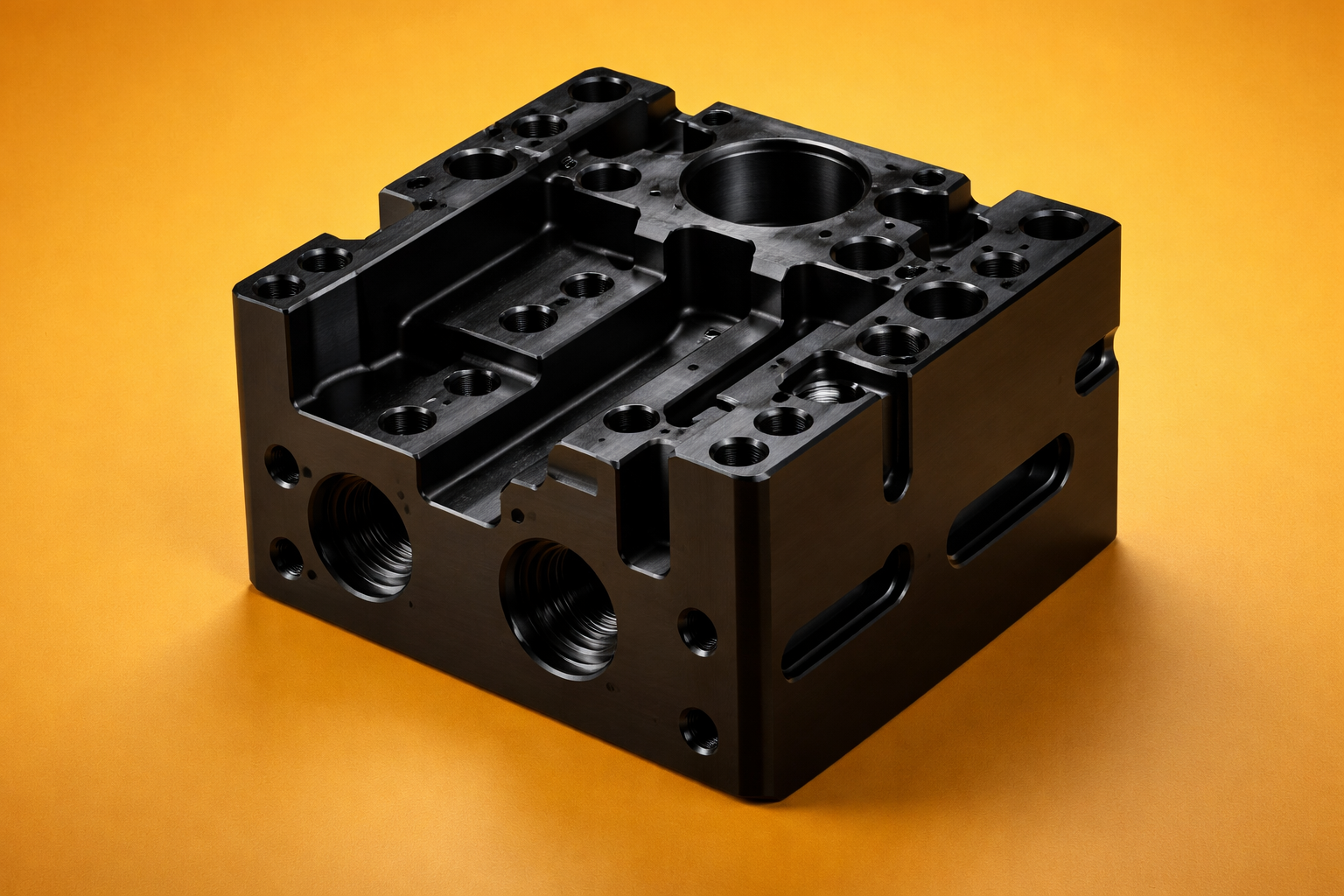

Rapid Tooling (Aluminum Moulds): Cost-effective moulds made from high-grade aluminum. Perfect for prototyping, market testing, and low-volume runs (100–5,000 parts) with rapid lead times.

Production Tooling (Steel Moulds): Hardened steel multi-cavity moulds designed for high-volume durability (100,000+ cycles) and cycle-time efficiency.

Advanced Capabilities

We handle complex part requirements with precision:

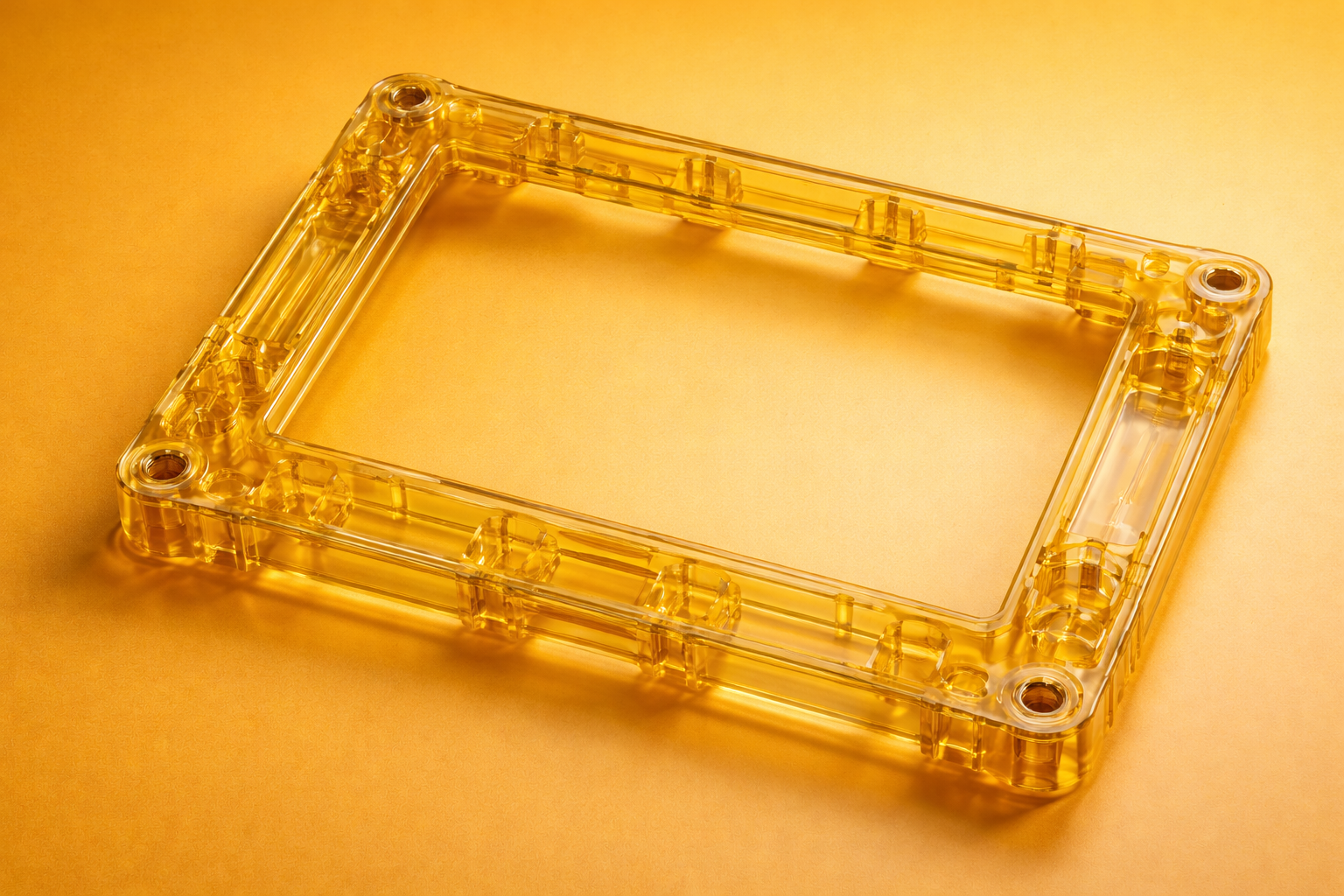

Insert Moulding: Encapsulating metal inserts (threaded fasteners, contacts) directly into the plastic part for superior pull-out strength.

Overmoulding: Combining materials (e.g., a soft-touch rubber grip over a rigid plastic core) to improve ergonomics and aesthetics.

In-House Tool Maintenance: Because we understand the engineering, we maintain and repair moulds in-house to ensure consistent part quality.

Material Expertise

We process a wide range of commodity and engineering-grade thermoplastics:

General Purpose: ABS, Polypropylene (PP), Polyethylene (PE), Polystyrene.

Engineering Grade: Polycarbonate (PC), Nylon (PA6, PA66), Acetal (POM).

High Performance: Glass-Filled variations, PEEK, Ultem.

Our Services

Contact Us

Request a quotation or have a question. Please include your files below in .PDF & .STP formats and we will reply ASAP.