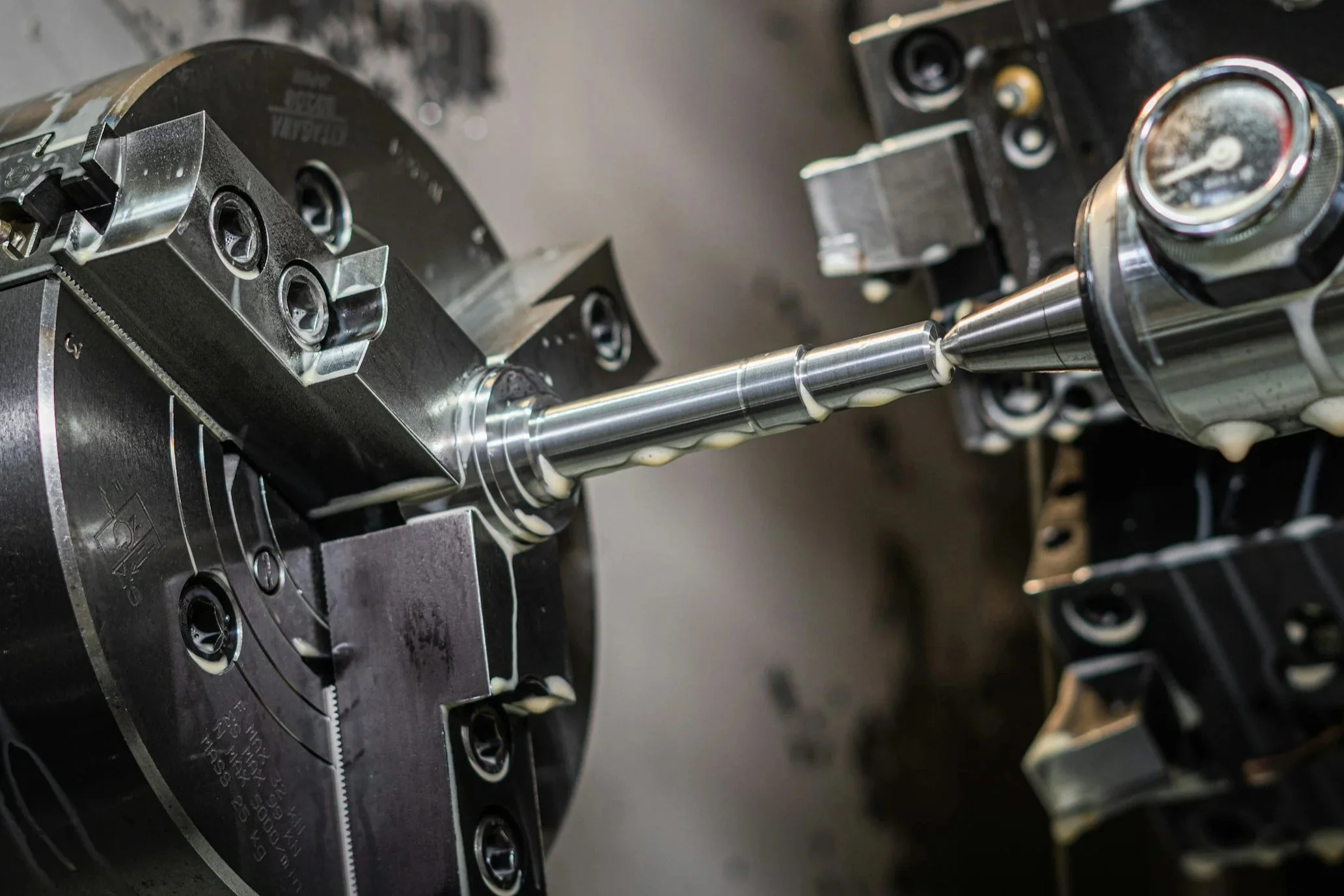

At Axion, we specialize in high-precision rotational components. From micro-machined pins to heavy-duty shafts, our turning department combines traditional lathe principles with modern CNC automation.

Capabilities

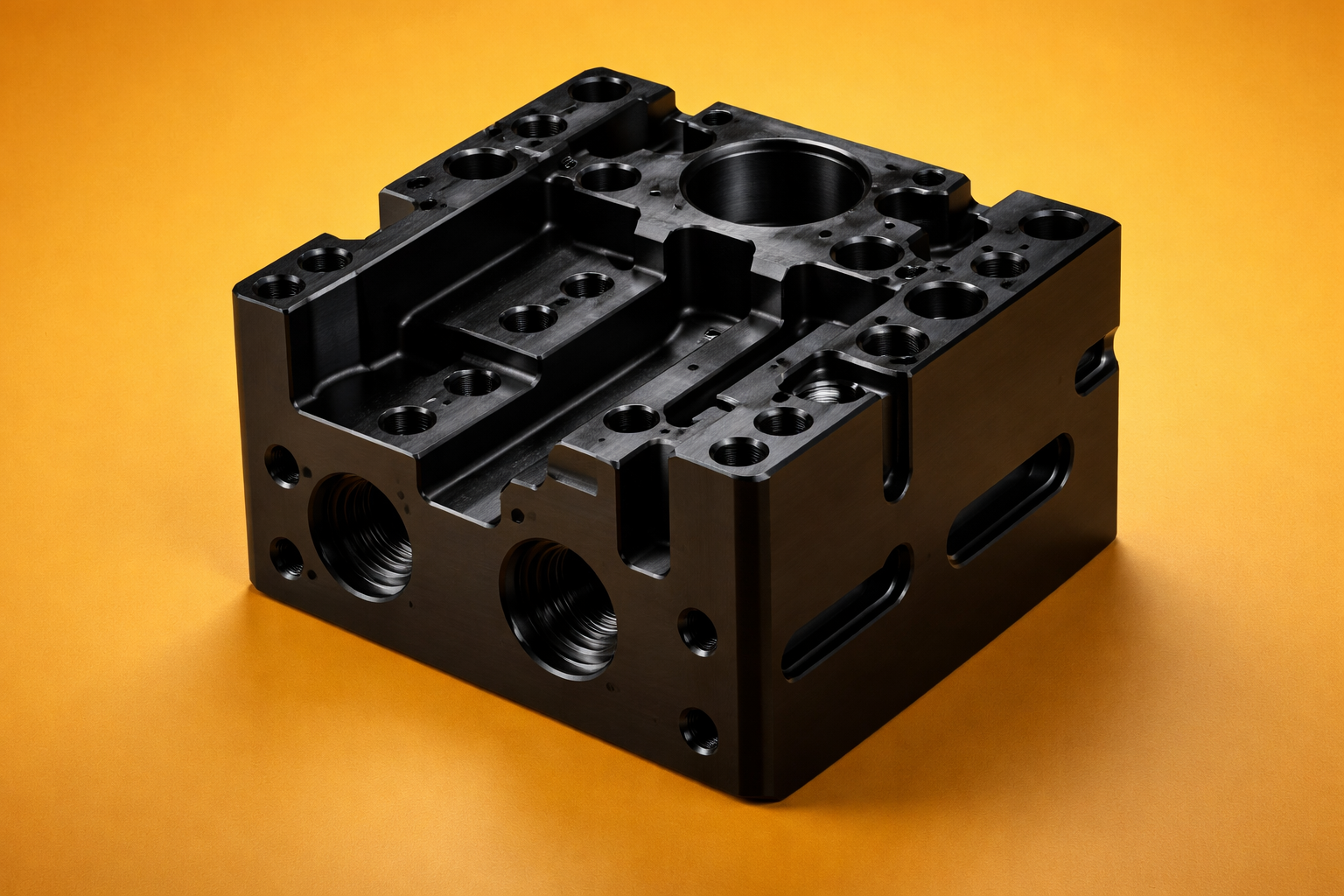

Our turning centers are equipped to handle complex features in fewer setups:

Live Tooling (Mill-Turn): The ability to mill flats, drill cross-holes, and tap off-center features while the part is in the lathe. This reduces handling and increases accuracy.

High-Speed Turning: Rapid production of pins, bushings, standoffs, and fasteners.

Hard Turning: Machining hardened alloys (up to 62+ HRC), often eliminating the need for secondary grinding operations.

Efficiency at Any Scale

We optimize our workflow for your volume requirements:

Rapid Prototyping: Quick-turn delivery for single shafts, custom fittings, and proof-of-concept models.

Volume Production: Automated bar-feeders enable "lights-out" manufacturing, significantly lowering unit costs for runs of hundreds or thousands.

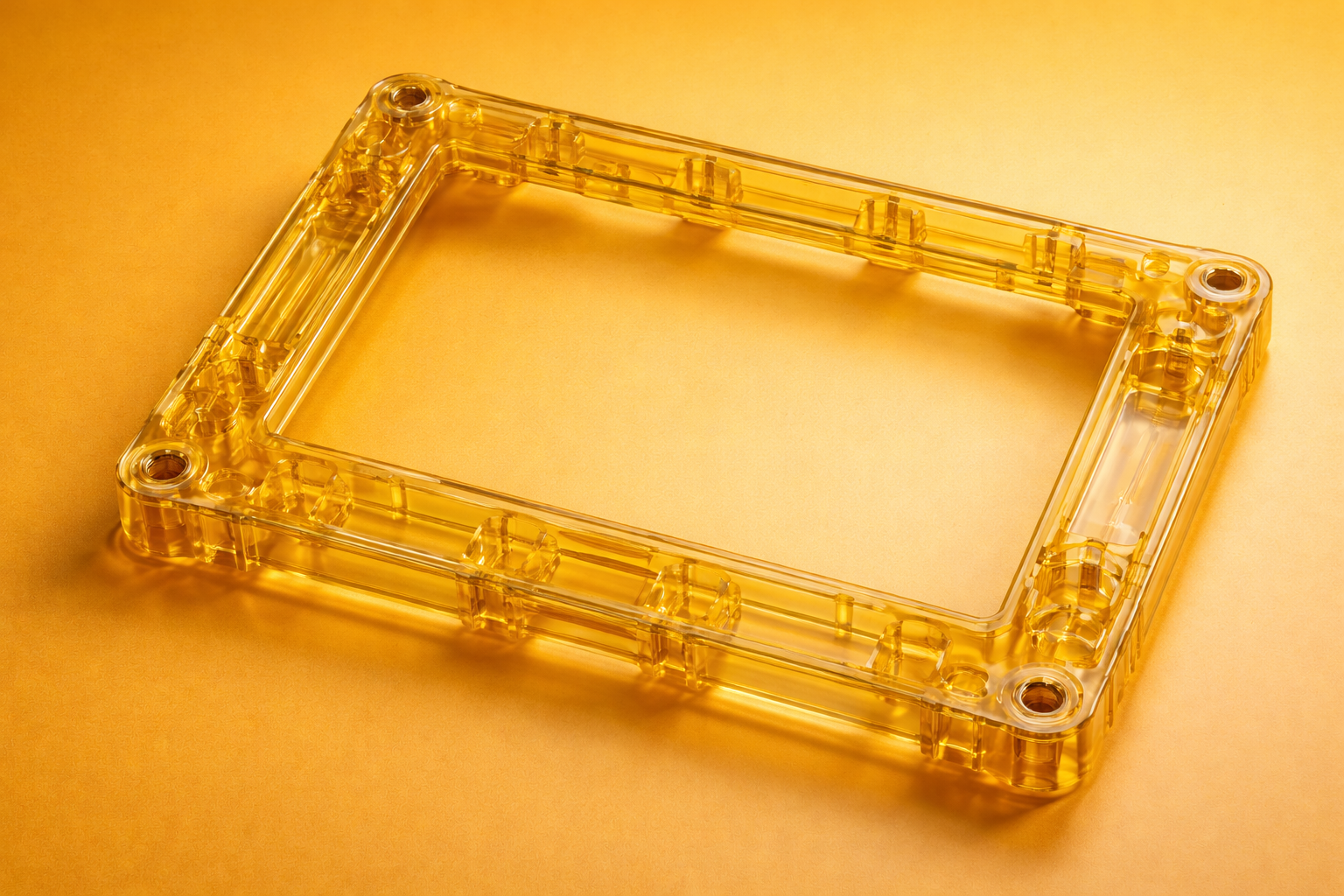

Material Expertise

We turn a wide variety of metals and polymers with exceptional surface finishes:

Aluminum: 6061, 6082, 7075, 2011, 2024

Stainless Steel: 303, 304, 316L, 17-4PH

Yellow Metals: C360 Brass, Bronze, Copper

Titanium & Exotics: Grade 5 Titanium, Inconel

Plastics: Acetal (Delrin), Nylon, PTFE (Teflon), PEEK

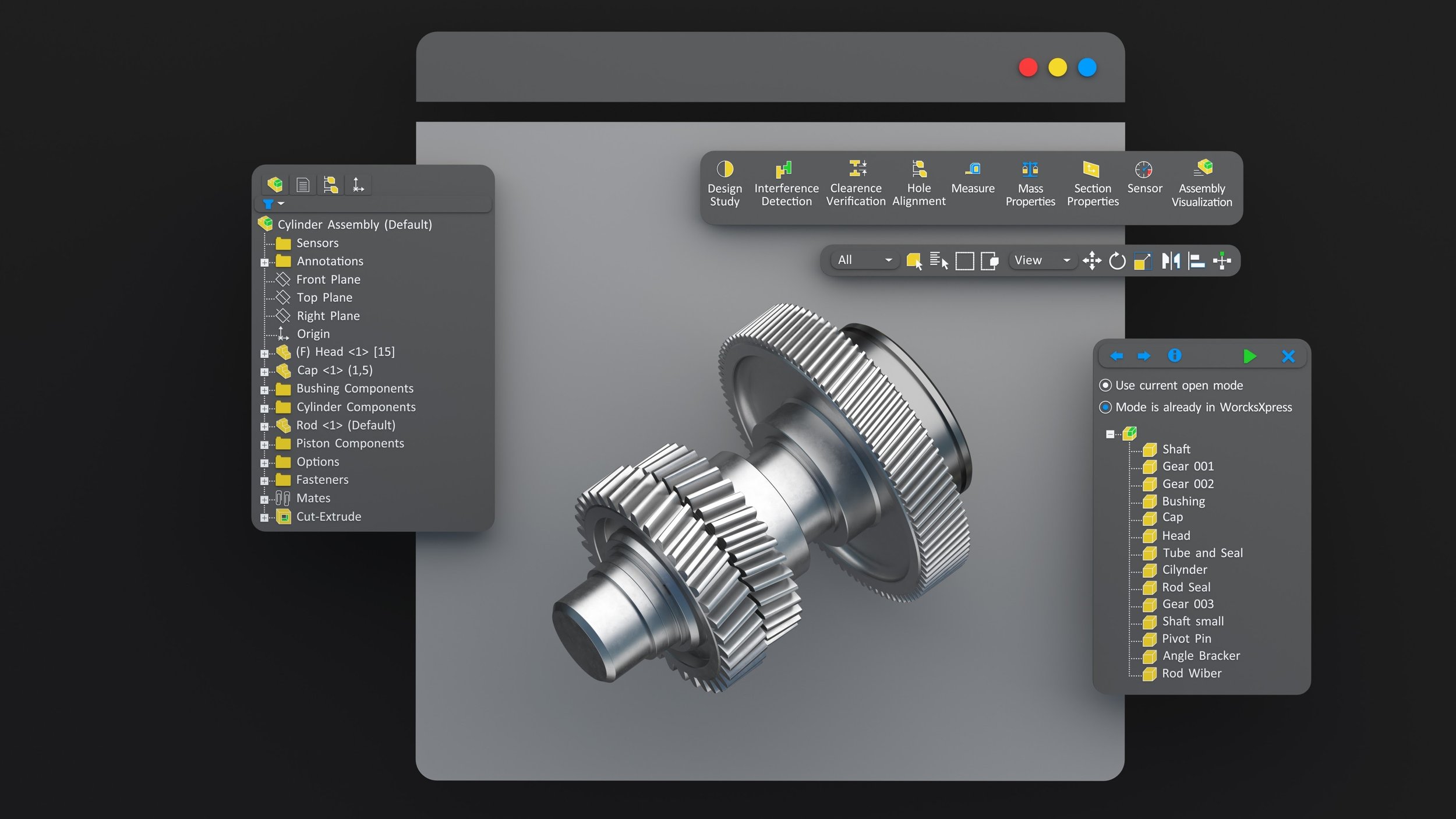

CNC TURNING Services

Our Services

Contact Us

Request a quotation or have a question. Please include your files below in .PDF & .STP formats and we will reply ASAP.